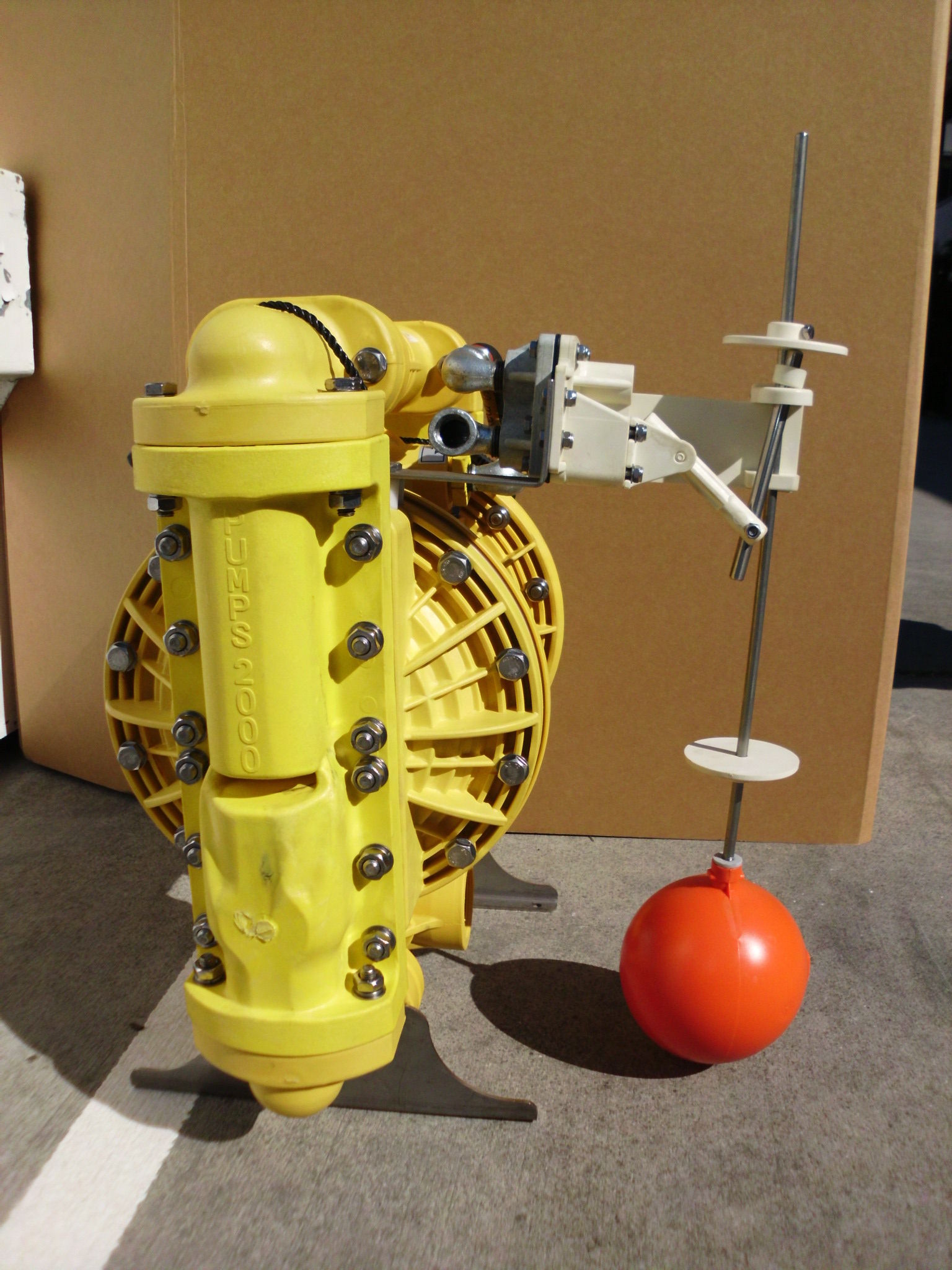

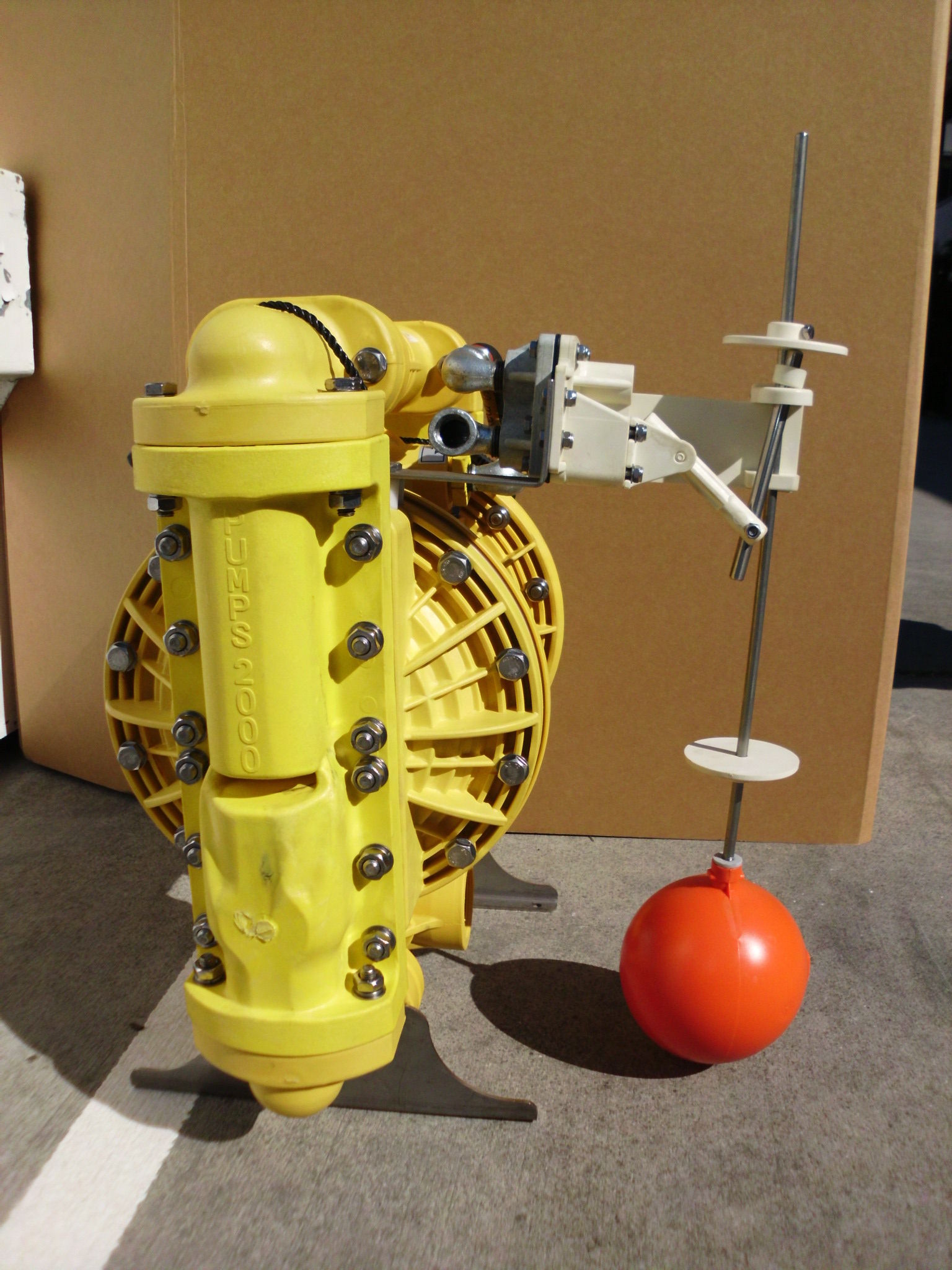

1 | Reduce air consumption and maintenance. |

2 | Turn the pump off before it runs out of water putting air into the suction and delivery lines causing priming problems. |

3 | Turn the pump off while there is still enough volume to flush sediment through preventing excessive wear of the housing and sediment getting under the valves reducing performance. |

4 | Using a WATER MONITOR FLOAT SWITCH in conjunction with a PUMPS 2000 PUMP where neither require lubrication prevents hazardous oil vapour getting into the atmosphere. |

5 | Adjusting the float switch to only turn on when there is plenty of water will increase the efficiency of the pump and the life of the diaphragm. |